Here follows a collection of introductory topics to explain our concerns about some traditional practices

Technical standards detail risk control processes. These processes and standards require periodic review.

Standards are best practices which serve as a guidance and don’t guarantee compliance in all instances, plus:

- new_releases There are specific applications areas where standard suggestions may become misleading

- people Users interpretations of the standards are to their best knowledge or situation, but this is not always correct

- swap_vertical_circle There are competing standards producing different numbers, hence, some of them match up with reality better than others

How to choose the best applicable standard?

- filter_1 Define the problem using its physics

- filter_2 Identify a choice of applicable standards

- filter_3 Use critical thinking on top of standard tools

- filter_4 Check with the relevant science

- filter_5 Do sensitivity studies – vary parameters and observe results

- filter_6 List assumptions and limitations

- live_help Do these match the risks ?

- import_contacts Refer the Code of Practice ‘Managing risks of plant in the workplaceopen_in_new’. In Appendix C it lists common standards for industrial plant design.

Now, the Big Issue: Nature's laws aren't sensitive to our awareness of them!

- multiline_chart To be realistic, we have to build models of equipment load and strength spectra

- bubble_chart Realistic in turn means probabilistic, since Load and Strength in operation are both random variables

- block Ignoring the probability terms compromises the analysis confidence, and even discredits advanced methodologies and tools. Bear in mind, this problem sits with the users, not in

the methods.

- thumbs_up_down 'Out-of-the-box' thinking is about modelling the 'reality' sufficiently enough to adequately answer your question!

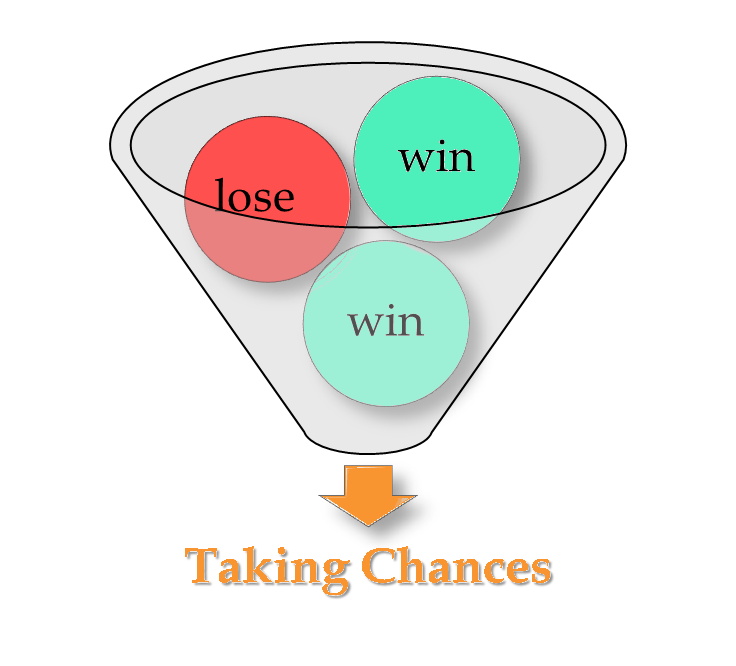

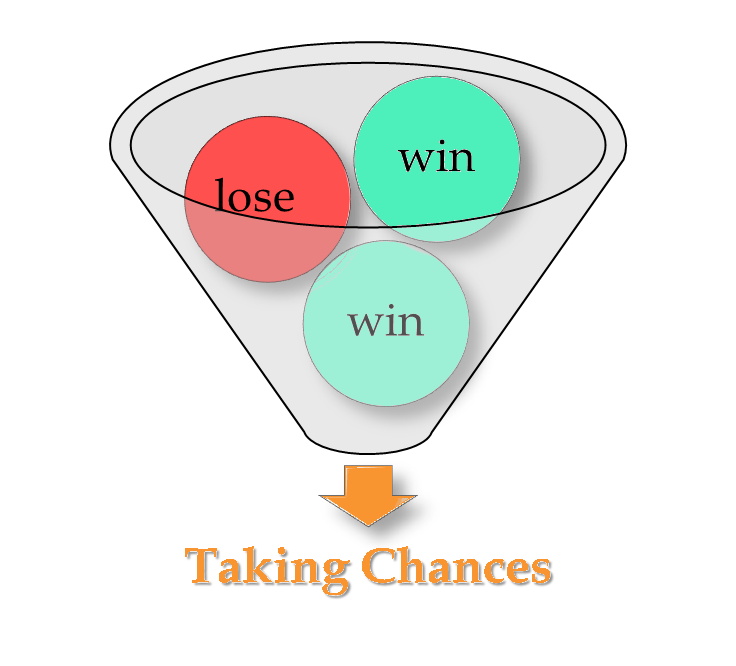

Would you like to experience a Probability of Failure (PoF)?

- Imagine, we are trying to extract out a single ball from this funnel without as much as looking at it at all

- Our chance to take the red ball will be 33% in 1st attempt, 50% in the 2nd and 100% in the last

- PoF increases along with the number of attempts, or with time, if chances are taken continuously

- Say, the red ball is now one in a million chance. How do you feel about finding it in the 1st attempt? How about the 1001st?

- When we operate plant equipment, the balls are dropping out from the bottom of the funnel at a certain rate, continuously.

- Moreover, each piece of equipment has its own number of red balls in a funnel, and may even (by design) have a number of different funnels, so it can be continuously replenished by operational damage mechanisms

(corrosion, fatigue, major force etc.).

- When you consider this, do you still feel confident about using qualitative risk matrices for integrity risk assessments?

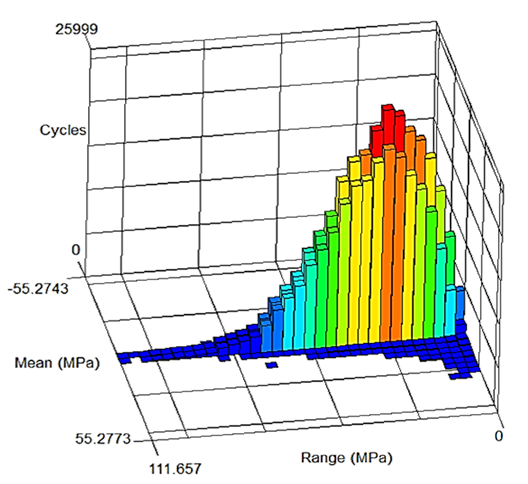

Stress design requires a realistic system of loads to be identified and screened, versus the material strength

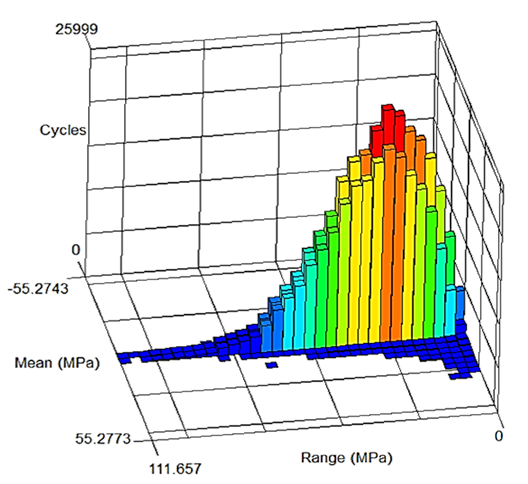

- In the above topic of ‘probability’ we have identified that real load spectra are random. These spectra in fact result from numerous random loads superimposed over time. An example of a stress spectrum is shown in the picture.

- In addition to random loads, material quality and strength also vary in a random manner. One cast part may be stronger than another. One casting batch may be weaker than another.

Why do material properties vary?

- Microscopic material imperfections are always there to limit equipment resource, e.g. micro-cracks, pores, inclusions, and even grain boundaries grow into cracks with time. Corrosion also starts from the weakest points, such as from coating or oxide layer faults.

Safety Factors vs. Detailed Stress Analysis

- Applying safety factors in design is necessary when viewing random load and resistance parameters.

- But there is much more value to be gained when safety factors are linked to PoF and life expectancy targets.

- Finite Element Analysis (FEA) is an indispensable part for cutting (some) corners of stress assessment.

- At QUANTY our philosophy foresees using FEA, together with probabilistic considerations, as a sufficient and robust solution.

- Whole Pro FE Analysis. Ask us how to!

Our Value Proposition:

We prove to our clients and peers that their problems can be resolved in a comprehensive and risk proportional manner.

You are welcome to visit our editBlog and find a range or popular articles addressing not-so-obvious integrity engineering problems.

Please feel free to message us mail_outline to learn more about our scientific Innovation portfolio and receive Free Trials of our solutions.