We know the Science. We put it into Practice. We proportion it to risks for Smart Cost Controls

We have mastered a spectrum of ingredients:

- monetization_on Risk Cost analysis strategy, including HSE risk components

- flash_on Probability of Failure (PoF) estimates

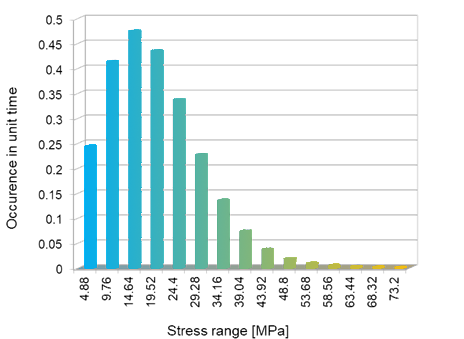

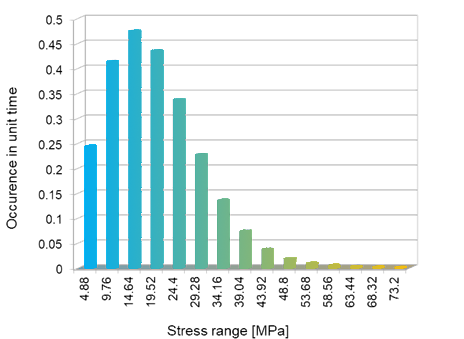

- equalizer Statistical analysis of damage

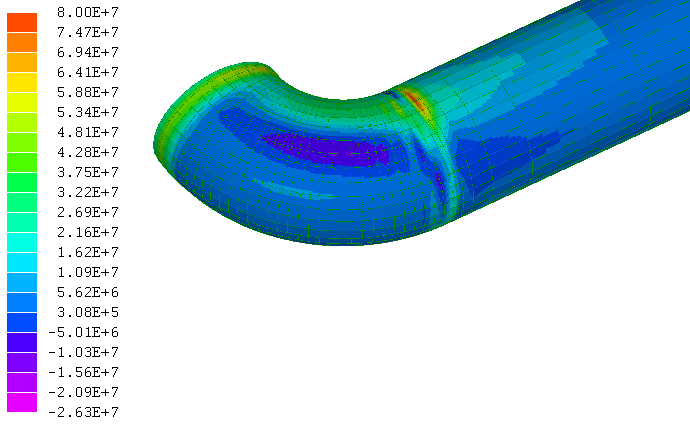

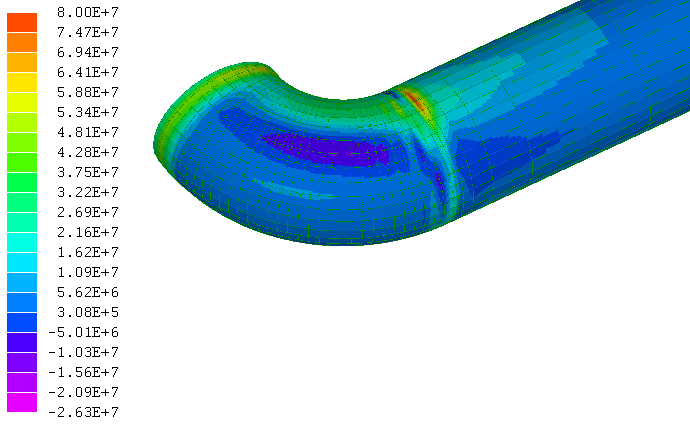

- multiline_chart Applied material strength, fatigue, FFS

- functions Structural stress and dynamics (FEA)

- flight_takeoff Other special engineering tools (RBI, NII)

- timeline We advocate relevant improvements to technical Standards

We apply the above ingredients to resolve:

- all_inclusive Operational constraints

- import_contacts Regulatory frameworks

- trending_up Expectations and drivers

- trending_down Tight integrity budgets

- security Safety aspirations

- filter_1 We do this consistently from the 1st principles, and:

- filter_2 We apply critical thinking as required for realistic outcomes

Our Value Proposition:

We do perform Integrity Analsyis for a wide spectrum of operational damage mechanisms (corrosion, cracking and more).

We do it strategically from the top level of risk management practices down to the specific damage science and data.

As a result, the analysis outcomes are practical and the analysis uses an optimal level of complexity, and is budget-wise.

Please feel free to message us mail_outline to learn more about our Innovation portfolio and possibly receive Free Trials of our solutions.

verified_user We are deeply familiar with oil&gas plants integrity, but not limited to, as we know the topical Nature Laws

school We are extensively experienced, qualified and certified to pioneer the New Integrity Management practices